© Catharine Ellis, as posted to the blog: Natural Dye: Experiments and Results

Dyeing

The leuco color of the fermentation vat will be green – not the yellow color that the quick reduction vats produce, as referred to this in blog post #3.

When dyeing, keep all textiles in the upper portion of the vat, so that they do not come into contact with the plant material and lime that have settled to the bottom. The quantity of these settled materials will increase over time. A net bag, such as a mesh laundry bag, suspended in the top of the vat is very flexible yet will contain the textiles and prevent them from getting “lost in the bottom”. It is easy to adjust how deep the bag sinks into the vat. Exposure to excess material at the bottom of the vat will result in uneven dyeing.

Important: Always oxidize the textile thoroughly before additional dips into the vat. Unless oxidation is complete, indigo that has not been oxidized on the textiles will revert to leuco indigo when returned to the vat.

Long dips vs. short dips in the vat – how many dips?

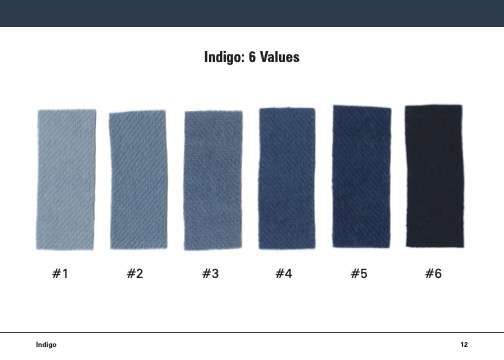

The ability to control shades of indigo, from light to dark, is one of the greatest challenges for the dyer. Some level of control is necessary to achieve a full range of blues, which also makes a palette of mixed colors such as greens and violets possible.

Preparing the various shades of indigo for The Art and Science of Natural Dyes Studio Formulas Set was challenging. I used two different fermented vats: a weak vat and a strong vat. I had waited many months for the “weak” vat to become “weak”. I wanted to achieve the most evenly dyed textile possible.

The palest of colors was dyed three times, for one minute each dip, in the weak vat. The darkest shade was immersed 6 times, 20 minutes each dip, in the strongest vat.

Long immersions in the vat will result in colors that penetrate the textile the most. Additional dips will always result in more even dyeing. Darker shades will always be more lightfast than pale ones.

Finishing the indigo dyed textile

Once the dyeing is complete:

- Allow the textile to dry completely before rinsing and finishing.

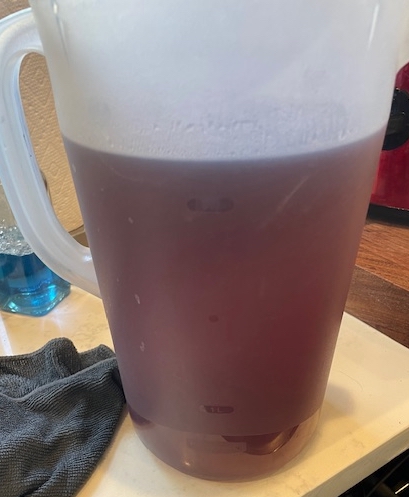

- Rinse in water – any temperature. The rinse water will be much browner than the rinse water from other vats. This is likely due to the organic materials (bran, etc.) suspended in the dye solution.

- Rinse several more times until the water is no longer brown.

- Soak in cold water overnight, then rinse.

- Soak for an hour in water to which you have added vinegar to make a weak solution: (approx. 15 ml white vinegar to a liter of water)

- Rinse again in clear water

- Finally, boil cellulose textiles with a small amount of neutral detergent, such as Orvus, synthrapol or Dawn© dishwashing detergent for 10 minutes. Protein fibers, which may be damaged by a vigorous boil, need to be gently brought to a near simmer 82°C / 180°F. The boiling expands the indigo molecule and also releases any unattached indigo on the textile. The final rinse should be mostly clear of any color.

Photo of rinse water, sent to me by a dyer, with the following comment: “The four tea towels and three napkins were dyed with six ten-minute dips. They were dried. I then soaked them in water for several hours. Dumped the brown water soaked again and dumped brown water. Soaked overnight and the water was clear.”