Eucalyptus is not native to where I live but I have watched dyers (with a bit of envy) from other parts of the world use these plants as a source of color and tannin. Each year I grow a plant or two for experimentation. These experiments have led me to some interesting observations.

The variety commonly found at our local garden center is Silver Dollar Gum (Eucalyptus cinerea). A friend, visiting from Australia, fondly recognized it in the garden as “gummy”. It will grow as an annual here and I always dry the round “silver dollar” leaves for dye. Sometimes I can even acquire them amongst the floral arrangements in the local grocery store. This year I had a additional variety (Eucalyptus globulus). It was grown by a friend from seeds that she brought from a tree in her yard in Ethiopia.

Dye tests were done on wool, both with and without an alum mordant, using dried leaves at 100% of the weight of fiber. Plants contain many different colorants. In the case of the Eucalyptus leaves, they contain both a flavonol and a tannin. The flavonols are typically yellow in color and require a mordant to attach to the fiber. The tannins produce a variety of colors and do not require a mordant.

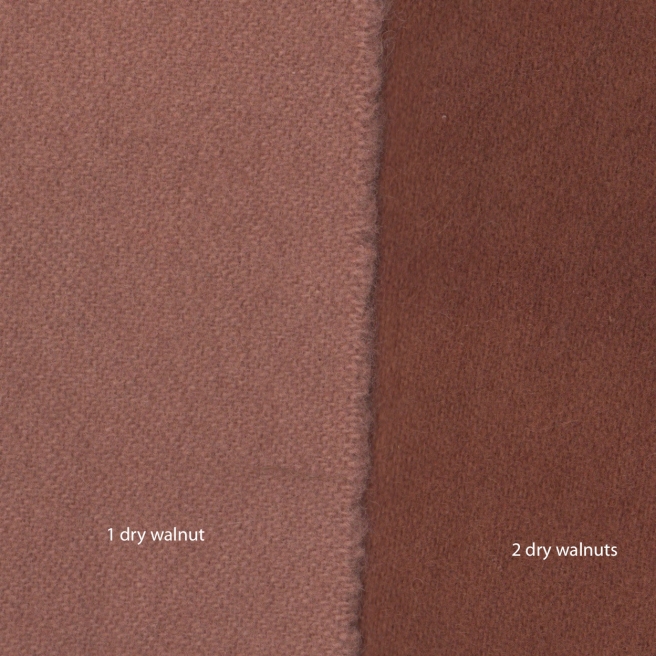

I placed non-mordanted wool fabric in the bath with the leaves. It was brought to a low simmer (approximately 190 degrees F). The color was slow to come but after about 2 hours the Eucalyptus cinerea resulted in a deep red/orange, while the Eucalyptus globulus turned a deep brown.

Alum-mordanted wool was dyed in a separate bath. The fiber quickly (within 30 minutes) turned a brilliant yellow from both varieties of eucalyptus. I removed some of the fiber from the dyebath when the yellow was still bright. As the rest of the fiber stayed in the bath, the tannins were released, changing the color of the wool from yellow to either a deep yellow/orange or a yellow brown. After two hours in the bath the mordanted fiber had been dyed by BOTH the flavonol and the tannin.

Several years ago I heard Michel Garcia say that the clearest yellow color from plants may come at the beginning of a dyebath, before any tannins are extracted. As the fiber stays in the bath with the dyestuff, the tannins are released and the color becomes deeper and duller. The eucalyptus is a dramatic illustration of this principle but other plant materials also indicate the same principle.

I have not yet completed lightfastness tests on any of these samples but they are in process. I would guess that the deeper, tannin-rich colors will be more lightfast than the brighter flavonols.