Turkey red is a process of dyeing cotton with madder. It uses oil to treat the textile before mordanting and dyeing to increase the brilliance of color and its ability to withstand washing. It was widely used in the 18th and 19th centuries.

A few years ago, Joy Boutrup and I did some quick tests together. We treated cotton with Turkey Red Oil. But the results were not good and so I abandoned it. Admittedly, I did not do further research at that time.

Following Maiwa’s online class, Natural Dyes: Alchemy Chemistry Craft, a small group of colleagues and I began a “study group”. Both the class and the study group have been a catalyst to delve a little deeper into some processes, including Turkey Red. Here are some of the results of my own testing and observations. This time I prepared myself better, did lots more reading and research and have been quite intrigued by the results.

My starting point was Julie Wertz’s new book: Turkey Red (Bloomsbury, 2024). In this book Wertz does an excellent job of presenting its history, some chemistry, and the series of steps involved.

Turkey Red Dyeing is a process by which cottons were treated with oil prior to mordanting and dyeing (or printing) using madder. It was practiced regularly in the 18th and 19th centuries in Europe and, I believe, some in the US. The result is a brilliant red dye color that is very fast to washing. It was an important discovery in the textile industry, though its roots likely go back much further to madder dyeing in India where oils were commonly used centuries ago to treat cotton textiles. Oil is also used in Indonesia prior to mordanting and dyeing cottons with Morinda bark (Morinda citrifolia).

It is believed that the oil combines with the mordant and then with the dye, making a compound that is faster to washing and light. All the literature refers only to its use with madder red. To the best of my knowledge, no other dyes are ever mentioned relative to the oiling process.

Turkey Red Dyeing was usually done on unbleached, and non-mercerized cotton. These cottons do not have an affinity with mordants and thus are more difficult to dye with deep, saturated red colors.

Jim Liles, in the Art and Craft of Natural Dyeing discusses the Turkey Red process in some detail and includes recipes. My other resources include old industrial dye manuals* from the early 20th century. These are the same manuals that Joy and I used to develop some of the recipes in The Art and Science of Natural Dyes.

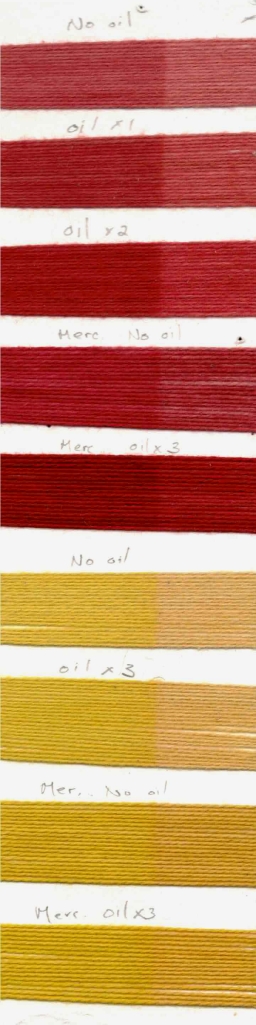

The Process: Un-mercerized cotton yarn was scoured thoroughly and allowed to dry. The dry yarn was then immersed in a 50% solution of Turkey Red Oil and water, then dried again. Multiple oil treatments are recommended, drying in between each. I oiled and dried the yarn up to 3x.

All samples were dyed using ground madder root @ 50% weight of dry fiber. I did not use oil in the dye bath or as an after treatment, as some recipes recommend.

My initial tests do indicate the effectiveness of the oil treatment. A deeper red color results after the treatment with oil. A single oil immersion resulted in a slightly deeper shade of red, but three oil immersions in the oil (drying in between each) resulted in a much deeper color. What would happen if it was oiled 4-6 times – which is recommended?

Oil applied to mercerized cotton yarn also illustrated the effectiveness of the treatment. Mercerized cotton always takes up mordant and dye more readily without any additional treatment. Clearly, the oiling did increase the dye take up even more.

An interesting fact: John Mercer, who invented the mercerization process in 1844, also has his name on the patent for Turkey Red Oil. Mercerized cotton always dyes more easily and results in deeper colors with any type of dyeing. Perhaps, when mercerization became common, the need for the labor intense process of oiling was no longer necessary or financially viable.

Follow-up question: All references to Turkey red dyeing use madder as the dye. Is there a bond made only between the oil and the mordant? Would oiling of the textile prior to mordanting and dyeing with weld or another dye also result in a deeper color?

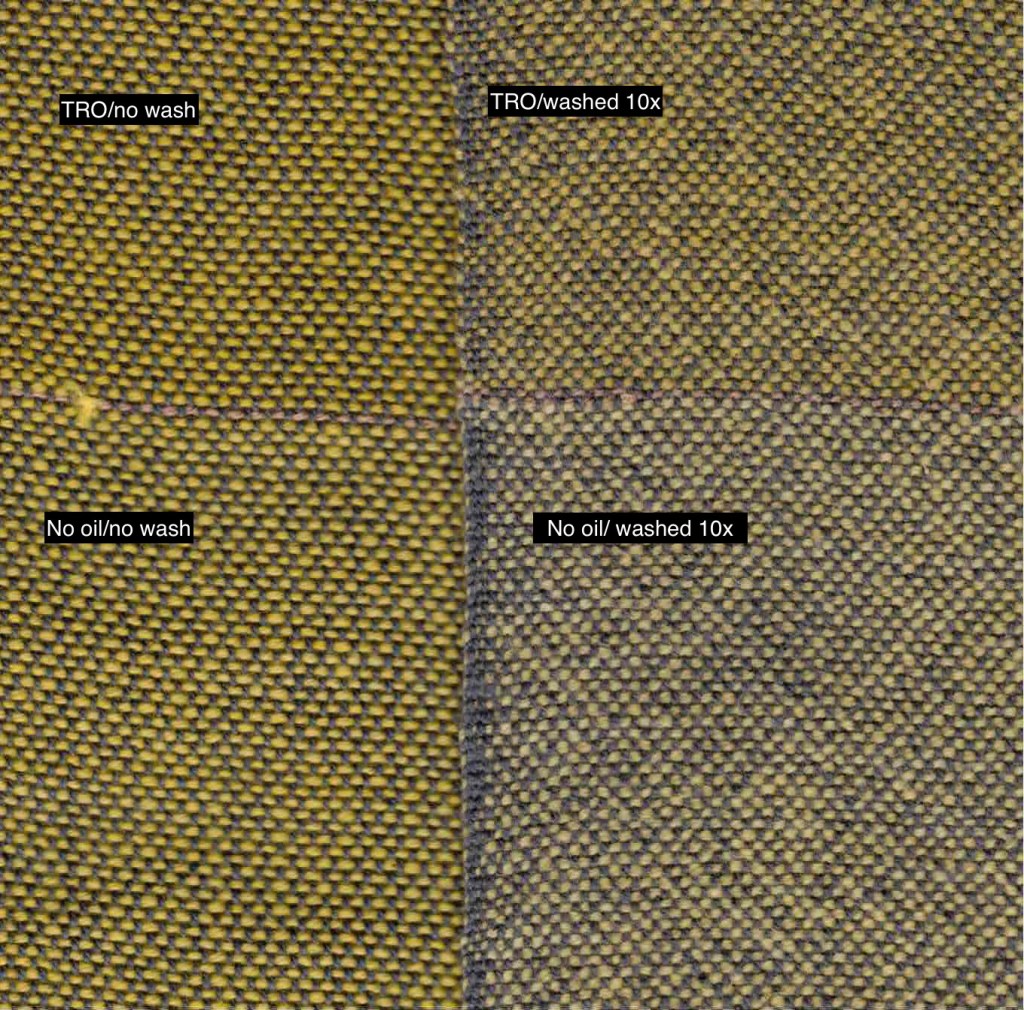

Initial testing indicates that the oiling of cotton prior to dyeing with weld results in a slightly deeper color but it isn’t nearly as dramatic as the madder dyed textiles.

After completing lightfast tests with both dyes, I observed a subtle difference in the way they reacted to light, taking into consideration the relative “before” and “after” of each dyed yarn following 3 weeks of exposure to direct sun.

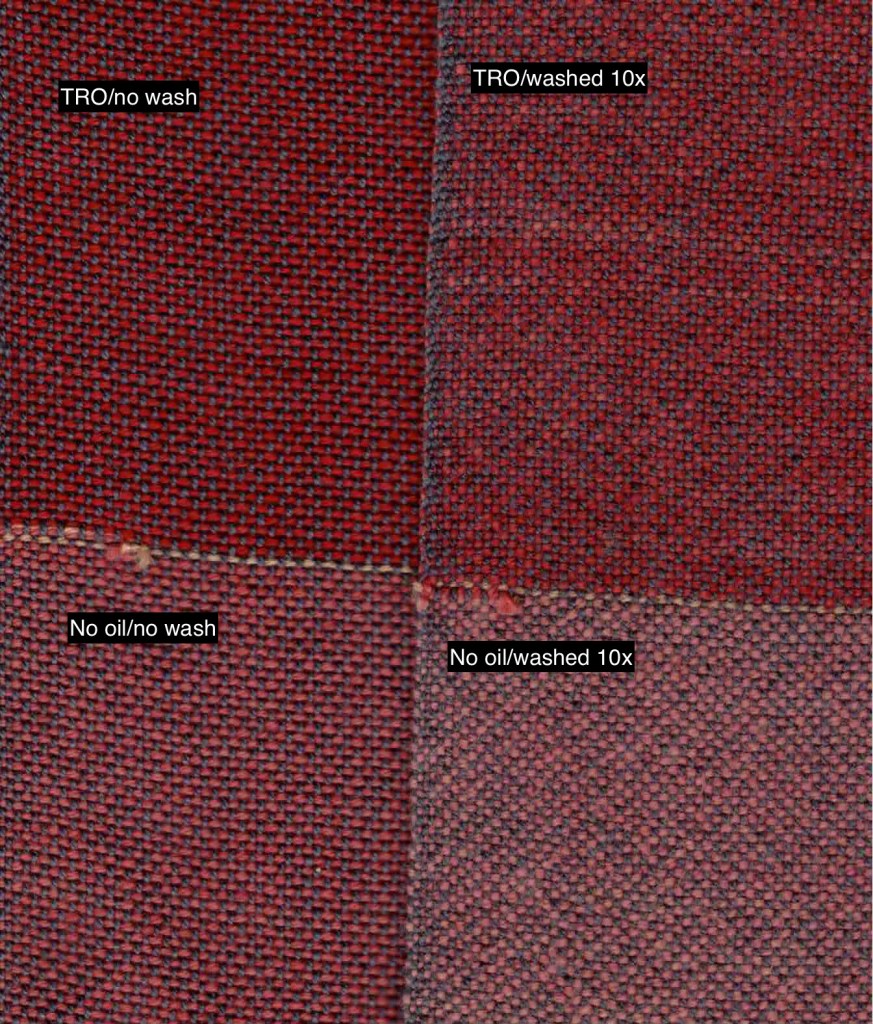

Wash fast tests, on the other hand, were much more dramatic. I used yarns that had been dyed both with and without the turkey red oil treatment. The yarns were then woven into a cloth with a dark grey warp. After only 10 regular wash cycles in my machine (along with the rest of my laundry), I observed a significant difference in the color loss of the dyed yarns with both the madder and the weld.

Once again, I am humbled by the research of dyers who came before us. I will seriously consider using the oil treatment when making textiles that could be laundered frequently.

*General Dyestuff Corporation, Manual for the Dyeing of Cotton and Other Vegetable Fibers (1936)

Kneckt, Rawson, Lowenthal – Manual of Dyeing, Volumes 1 & 2 (1893)

I so appreciate this post…

What is Turkey red oil? Where to get it?

Turkey red oil is sulphonated castor oil and is readily available online from suppliers that have soap making supplies, etc.

Thank you Catharine! We just dyed with madder in our dye garden at the botanical Gardens. I had no idea that oil treatment has this impact!

Would you be ok if I share this article with our group? We are missing Donna so much and she always has been our go to for so many questions!

Also, another thought came up. We used our own madder root and we got no the strong color we were hoping for. Do you think when we were grinding up the madder that it got overheated in the grinder and that we lost some of the color?

I hope you are doing well and I proudly wear my shawl I made from the yarn we dyed in your workshop several years ago!

Inge Fasshauer

Of course you can share this. Yes, I miss Donna too…. I don’t think that the heat created by grinding would have an effect on the color. I like to use a long, slow dyeing process… but there are so many variables…..

thank you

Thank you for the fascinating article! I haven’t tried Turkey Red Oil yet, but I’m inspired to give it a try now. I noticed you’ve transitioned to dyeing yarn samples instead of fabric—was there a particular reason for the switch? I’m dyeing with my home-grown madder for the first time and observing how different tannins and the extended, room-temperature dye bath influence the color. The result is such a beautiful shade!

I just had a need for yarn this time! Let me know if you try it and what you observe.

Thanks Catherine I really appreciate you sharing this information.I found it very interesting.Sincerely Linda Spence Sent from my iPad

As always I very much appreciate your work and generous sharing Catharine! Dreaming of joining your workshop next summer honoring Donna. Much love from southern California.

-Liz

That would be wonderful if you could join us next summer! And a good excuse to visit the mountains of NC!

Catharine,

Thank you for this detailed look! I also formed a study group after taking the MAIWA classes and one of the dyes we’re going to try this weekend is alkanet. I’ve read that some of the colourant may have an affinity for oil and now I’m thinking of trying this process too, to see if the color deepens.

Do let us know!

Fascinating! I have hesitated to dye with madder because of fading, and keep it in my dye pantry for feeding my indigo vat. If I do try the Turkey Red Oil process, will some of the oil come off in the madder dye bath, and do you think it would affect an indigo bath? If the oil floats, maybe I could skim off the fat (like soup) or siphon (like wine)? Thank you for the continuing work you do to systematically understand and improve natural dyeing.

The oil attaches pretty strongly to the textile, and I was not aware of any oil free floating in any of the mordant or the dye process. When dyeing with indigo and madder, you might want to dye your indigo first, then oil the cloth to prepare for mordanting and dyeing with the madder

Thanks, as always, for sharing your careful research. I have looked at this treatment from an “this is an interesting historical technique” but now I am tempted to try it.

Joyce

Thank you for sharing your wonderful knowledge. I have tried the treatment of cotton with turkey red oil in the past, but I was disappointed with the results. Now I realise that multiple treatments are necessary to achieve the red I was looking for. The resulting improvement of lightfastness and washfastness makes the added labor involved worth it. I’ll have to add it to my list of future dye experiments.

Grace

Dear Catharine,Thank you for sharing these fascinating experiments! I

Thank you for sharing this Catharine, your results are great. I’m keen to try this method but am unsure about the oil to use. Traditional turkey red oil is sulfated castor oil, is this right? This is expensive and difficult to get hold of in the UK, I wondered if you knew of alternatives. Thanks!

Harriet, I opted to use the Turkey Red oil, as it was the easiest and most direct approach. Industrial practices switched over to this as soon as it was available. I know that the sulphonated castor oil is used and sold for soap making etc., but I don’t know of it’s available in the UK. The old recipes call for rancid oil and many more steps to make the oil suitable, which I was just not wanting to do. Maime’s Schoolhouse does have an online self directed class that I believe takes you through a process that includes soap making. I have not done it but I know others who have and their results have been good. https://www.mamiesschoolhouse.com/online Hope that helps. Catharine

Thanks Catherine! I have managed to order some.